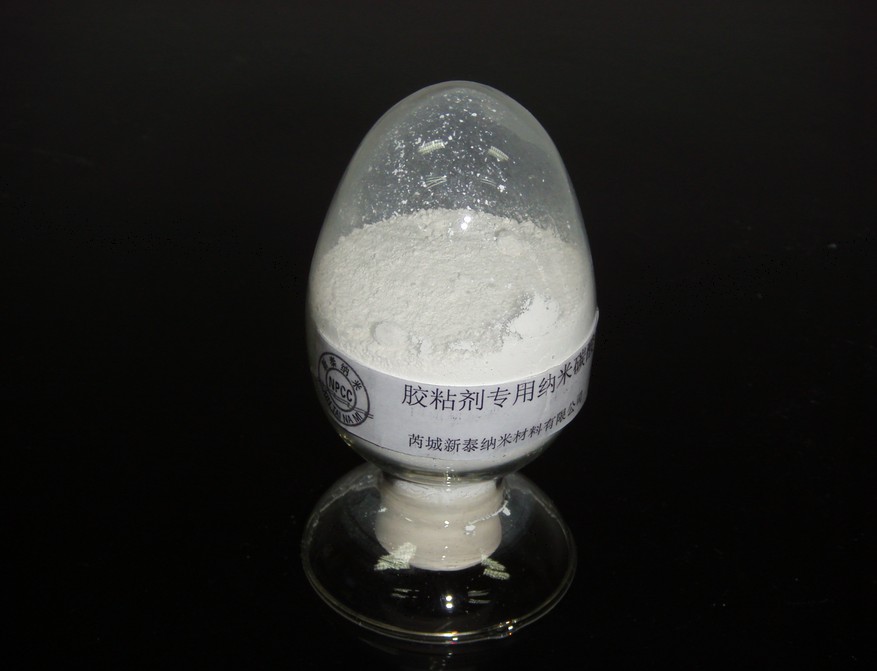

Our nano-precipitated calcium carbonate is a special stuff in the process of manufacturing modified plastic with quite nice applied performance, such as smaller diameter, narrow distribution, regular crystal, higher whiteness, better dispersion and lower moisture etc.

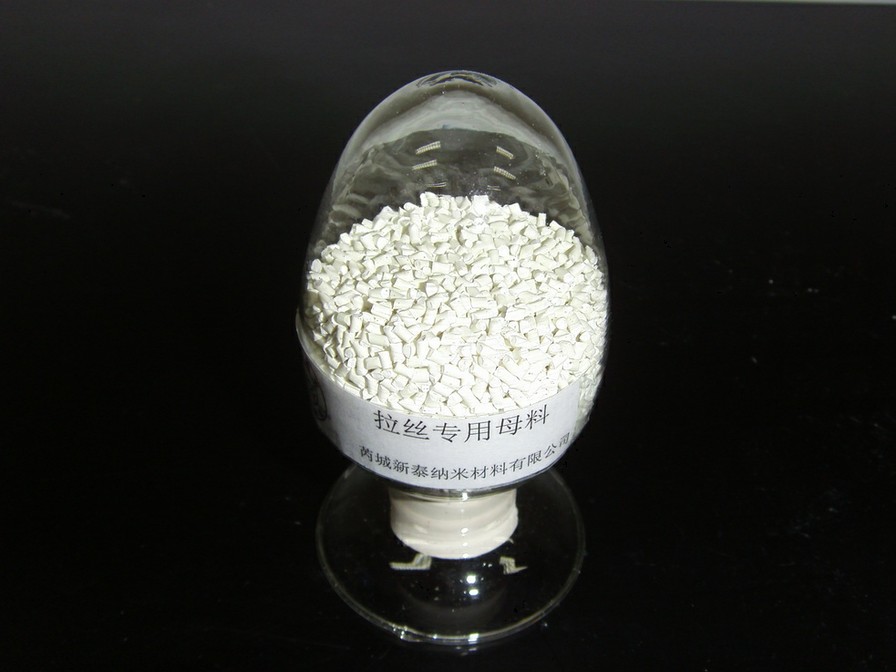

4.To be widely used. It can be applied in varied modified plastic made from polyethylene(PE), polyvinyl chloride(PVC), polypropylene(PP), polystyrene(PS), acrylonitrile-butadiene-styrene(ABS) as well as chloridized polyethylene(CPE), and it can also be applied in some small parts on the fields of producing plastic steel window, pipe materials,etc.